News

Precast concrete wall panels in Hanoi – HRC Vietnam

In construction, finding a solution that is both cost-saving and shorten the construction time but still ensure technical requirements and safety is what every investors want. Will precast concrete wall panels meet the above requirements. Let take a look the information below.

Should be used precast concrete wall panels in construction?

What is precast concrete wall panels ?

Precast concrete wall panels are building materials with high levels of bearing, bendability and water resistance. This is one of the materials that is gradually replacing brick walls, which is very popular in the construction of houses and industrial works because it helps investors save costs, protect the environment and have a long life.

Characteristics and structure of precast concrete wall panels

Depend on the production process and materials, the precast concrete wall panels will have different characteristics and structures. The building materials market is currently favoring some types of precast concrete as follows:

Cemboard cement precast concrete wall panels

The composition of cemboard precast concrete wall panels includes: Portland cement, fine sand (ultrafine silica sand), cellulose. These ingredients will be mixed together, then go through the rolling system to help the product get a certain hardness.

The production technology of Cemboard precast concrete slabs is made according to advanced European. The final product is hard, firm, well-bearing concrete slabs that withstand bending. The size of Cement precast concrete panels is quite diverse to serve many different construction demands

The thickness of the cement Cemboard sheet will depend on the purpost of using:

-

If used to make cellings for factory or construction in a high humidity position, the size of the concrete wall slab should be 3mm – 5mm.

-

If used to make partitions in the house, between rooms, it is recommended to choose cement Cemboard panels with a thickness of 6 – 10 mm

-

If used to make floors, mezzanine fake floor, lifting floor, factory floors … it is recommended with a thickness of 12 – 20mm.

Cement precast concrete panels are assembled together by supporting steel frame bars, fixed by screws, ensuring absolute safety, especially longevity not inferior to wall panels. Concrete poured according to the traditional method.

Precast concrete panel

Precast concrete panel is a combination of high-strength prestressed concrete beams, hollow concrete bricks, bonded by reinforced concrete layers, forming light panel wall panels.

Advantages of the panel wall:

-

Fast construction time: Because it has been assembled in advance by blocks of bricks, from the process of transporting materials to the construction site to the construction process is done very simply, quickly, saving money. time.

-

The price of precast concrete is much cheaper than traditional concrete poured on site.

-

Precast concrete panel has high bearing, bending resistance and durability.

-

Good sound & heat insulation.

-

Reducing environmental pollution due to the process of construction of precast concrete wall panels takes place quickly, do not carry out pouring concrete on the spot, so litmit the cause of dust.

Disadvantages of precast concrete panels:

-

Has same weight as traditional concrete pouring

-

Not the optimal solution for a home with a weak foundation

-

The cost of making the foundation of the building is not much different from the traditional floor

DURAflex precast concrete

The precast concrete slab that many people are interested in is the duraflex sheet. To produce this type of precast concrete, the raw materials are: white cement, limestone, fine sand, and cellulose fibers. The materials will be mixed in a certain proportion, then put through Flow on production technology - advanced European manufacturing technology, including compression and steaming at high temperatures.

DURAflex precast concrete before being put on the market will be checked quality for hardness, bearing capacity, resistance to moisture, mold, etc. Unqualified products will be rejected, qualified products will conduct cutting and grinding, then pack the goods and then transport to the warehouse.

DURAflex precast concrete slabs are diverse classified, depend on size, weight, thickness as well as the purpose of using. Each concrete slab usually has a thickness of about 3.5mm - 20mm, with 3 uses divided into 3 levels:

-

If making ceilings, balcony ceilings … it is recommended to use DURAflex precast concrete slabs with a thickness of 3.5mm – 5.5mm. This type has a high heat and humidity resistance effect.

-

If making outdoor walls, residential walls or partitions.. it is recommended to choose DURAflex panels with a thickness of 6 – 11.5 mm. This precast concrete slab is also heat resistant, very good insulation.

-

If making imitation cast floor, inn floor, mezzanine.. it is recommended to choose concrete slabs with a thickness of 12 – 20mm

On the market today, there are many types of precast concrete wall panels with diverse designs for you to choose from.

The trend of construction with precast concrete wall panels in Hanoi today

Over the past year, the economy has continued to suffer many impacts from the Covid-19 pandemic. In particular, the construction industry is also affected, especially contractors and construction enterprises. In addition, recent fluctuations in fuel and petroleum prices have led to a sharp increase in the price of construction materials in Hanoi. The rising price of building materials causes many difficulties for investors and businesses.

Many contractors and construction units tend to use affordable materials to optimize construction costs.

Therefore, many businesses and construction units tend to look for materials that help reduce costs, are durable, beautiful and environmentally friendly but still ensure the quality of the work. Precast concrete wall panels in Hanoi are considered the most optimal solution today.

This is a modern material in the construction industry, with low cost but high quality, high bearing capacity, fire resistance and waterproofing, helping investors and businesses reduce raw material costs, shorten the construction time. Construction time is much longer than that of conventional materials, and at the same time, it also contributes to reducing emissions causing environmental pollution.

Should be use precast concrete wall panels in construction ?

Precast concrete wall panels help to save cost

If you use traditional materials for the construction, it will take more cost and a lot of time. Meanwhile, precast concrete can help you overcome these above problems, both cost and time. These types of concrete wall cladding materials have a relatively low initial price, suitable for many customers. In addition, the precast concrete slabs are lightweight, making foundation work less labor intensive. Because the concrete slabs are precast, you can save time waiting for the concrete to dry, the curing process of fresh concrete and save human resources.

Suitable for all projects

Precast concrete wall panels have many sizes, so they are suitable for all projects, from affordable to high-end. Beside that, the product also has many different prices and brands for you to choose. You should choose the size of precast concrete slabs suitable for the type of work being built for the most efficient and economical construction.

Durability and high aesthetics

Precast concrete wall panels have many advantages such as good bearing, water resistance, moisture resistance, fire resistance, non-wraping, termites … Therefore, when used it for the works will retain durability with time as well as high aesthetics. Precast concrete panels satisfy the needs of the most demanding customers.

Eco-friendly

In addition to use materials that are safe for users, precast concrete panels also have the advantage of being environmentally friendly. Specifically, this is considered a green and smart building material when it saves maximum cost, time and labor. When the construction process is shortened, you will reduce the waste to the environment.

Compare construction costs when using precast concrete wall panels and traditional construction methods

Currently, houses built by the method of pouring concrete on the spot or built with traditional bricks all use iron, steel to make the frame, then the cement layer is poured into quite thick concrete slabs. This traditional method of building a house with concrete is quite expensive because you have to put large amounts of money into iron and steel materials. If you use precast concrete slabs to build a house, it will help reduce the cost by 25%-35%. In addition, when using precast concrete slabs, you can also save money on the payment of workers. In many ways, the use of precast concrete will be much more cost-effective than traditional construction.

Production process of precast concrete wall panels in Hanoi by HRC Vietnam

Hrc Vietnam's precast concrete wall production process in Hanoi goes through closed stages, carefully calculated and applies the most advanced technologies.

-

Steel processing: steel processed in the factory shoud make sure always news, dry, clean, especially the calculation of precision machining to reduce costs, increase efficiency and ensure the highest safety

-

Put steel in the mold: Hrc Vietnam's precast concrete uses alloy steel formwork, with a predetermined size instead of phased trunks, wood planks. Besides, reinforcement is installed correctly, quickly with a crane.

-

Pour concrete: Pouring concrete in a horizontal method helps to limit waste, scattering concrete out.

-

Surface finish: Since the concrete is poured horizontally, the finishing of the surface also becomes simpler.

-

Nursing: The concrete after pouring will be nourished by steam, maintained at a temperature of 50 °C for about 3-4 hours.

-

Remove the storage mold: After checking that the product has reached the standard hardness, remove the mold and move to the warehouse.

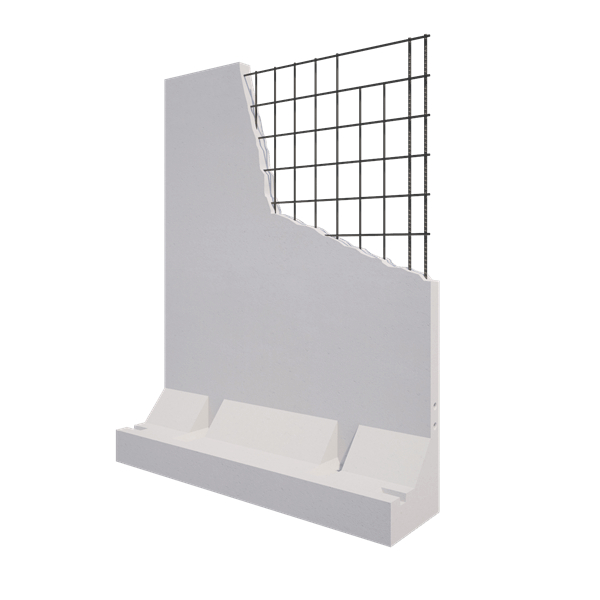

Some pictures of HRC Vietnam's precast concrete wall panels

Currently, the trend of using green and smart materials for construction is being chosen by many people, the most prominent of which is precast concrete slabs - the most optimal construction solution for all buildings. Here are some specific images of hrc Vietnam's precast concrete wall panels in Hanoi that you can refer to and choose.

W23030 wall panels with various types of sizes

W17035 wall panels suitable for use as fireproof partitions

>>> See more products of precast concrete wall panels in Hanoi are of high quality here.

Best concrete wall construction unit in Hanoi

One of the providers of precast concrete wall panels in Hanoi of high quality that you can choose from is HRC Vietnam. In the future, we aim to become a leading enterprise in the field of manufacturing and assembling precast concrete in Vietnam and Southeast Asia

HRC Vietnam is the best construction unit of precast concrete wall panels in Hanoi today

HRC Vietnam is currently trading a wide variety of precast concrete components with diverse designs, bearing capacity, good fire resistance, such as wall panels, fences, columns, sewer pipes, electric nails, bridge beams,... We are committed to bringing products of outstanding quality, carefully tested for structure before being transported to the construction site.

In addition, HRC Vietnam also has a modern production system, production process according to Japanese standards and technology, bringing precast concrete products with many outstanding advantages.

In addition to producing products, we also provide construction solutions, install types of wall panels, precast concrete fences for industrial works such as factories, warehouses, precast steel workshops. With a team of engineers, experienced and professional workers, we are confident to satisfy all the most demanding customers. To understand more about our process as well as our products, you can visit the hrcvietnam.vn website or call hrc Vietnam's hotline.

Precast concrete wall panels are the optimal construction solution for many investors, saving costs, construction time but still quality of works. In the future, this type of material is expected to completely replace traditional materials. If you need to find out more information or order precast concrete wall panels in Hanoi, please contact HRC Vietnam immediately!

.jpg)