News

Green building materials – saving resources, cost, safety but not everyone knows|HRC

Green building materials are growing in the construction industry and are gradually replacing other materials that polluted the environment in the past. To understand more about green building materials as well as the types of materials that are preferred for using today, let's refer to HRC Vietnam Green Materials for more details as below!

Which constructions can use green materials?

What are green building materials?

Green building materials are materials for construction, environmentally friendly as well as users. Currently, the production of green materials must meet the criteria such as consuming less energy to produce, not polluting the environment, having a long life cycle, reusable,...

Green materials

Green building materials bring benefits to investors and users such as:

-

Resource saving: Using green materials not only saves resources but also more flexibility in producing and supplying materials for the construction industry.

-

Cost savings: Materials that can be recycled and used thereby making it more cost-effective than traditional materials that cause waste.

-

Non-toxic and safe for users: Currently, the living environment is increasingly polluted causing negative impacts on the climate, epidemics, changes in ecosystems as well as human habitats.

Criteria to be considered green material

Using green materials is a good solution to help protect our environment as well as our environment. These are the top priorities of green materials:

-

It does not pollute the environment

-

High flexibility in design.

-

Reduce maintenance and replacement costs throughout using

-

It can be reused.

-

Limit noise pollution during construction.

Using green materials to improve the environment

Types of green building materials popular in the market

The purpose of the use of green materials is to build energy-efficient, environmentally friendly buildings in addition to architectural, aesthetic and usable elements. Therefore, the types of green building materials commonly used today include:

XPS Insulation Foam

XPS Insulation Foam Sheet is a soundproofing material, good insulation made from PS plastic with hard, expanded sheet pressed. This material is widely used in civil, industrial and public works.

According to recent researchers on the new works, the works using XPS insulation foam of about 15-18cm can save electricity consumption by about 343-344Wh/m2. This not only saves energy but also enhances the living space better.

XPS Insulation Foam Sheet - Soundproofing Material , Good Insulation

Insulation foam sheet has high mechanical strength thanks to the stability in the physical structure, which has a good preventative and moisture-resistant effect. The outstanding advantages of XPS insulation foam panels such as:

-

Noise resistance, heat conductivity, very good conductivity and high compression capacity.

-

Durable due to the sealed and foamy structure.

-

Waterproof, moisture resistant and highly corrosion resistant.

-

Low thermal conductivity, light weight, convenient for the process of movement.

-

The service life of the product is high can be used up to 50 years, the insulation capacity still reaches 80% compared to the original stage.

-

Persistence in harsh environments.

-

Prevent the risk of rust, thereby helping to increase the life of the building.

-

Helps reduce heat radiation from the roof to the home space, helping the internal temperature to always remain at a stable level.

-

Lightweight, supports cost savings and optimal energy.

Moreover, the insulation foam sheet will have some outstanding points compared to pressed insulation foam such as foam plates with more uniform surfaces and concave cells. Polystyrene material to make XPS panels is very safe for users and environmentally friendly. Therefore, this material does not cause any dangerous toxins to evaporate, is not moldy and corroded but can be reused, recycled.

Green wall cladding wood

Australia's Weathertex wood is pressed with steam pressure, pressed from wood crumbs of harvested branches and has 3% chemical-free and non-toxic adhesives and 97% wood crumbs. Green wall wood is a green material that does not use natural wood but is harvested from plantation wood.

Australia's Weathertex Wood

This type of wood cladding is often applied as a building wall that can be used for both indoors and outdoors. The advantages are superior to natural wood such as not warping due to withstanding harsh weather outdoors, good fire resistance, durability over time,...

Organic roofing sheets

Organic roofing sheets are made from cellulose (organic fiber), asphalt and acrylic waterproofing agent (waterproofing agent) by mass pressing. As a result, the organic roofing can withstand extreme weather and withstand stormy winds well at a speed of 190km/h with heat resistance, noise resistance, heat conductivity and good insulation.

Organic roofing sheet with good heat resistance and insulation resistance

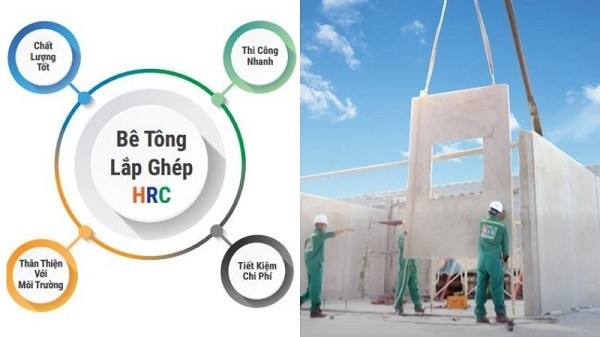

HRC wall panels meet green material criteria

Green Materials HRC Vietnam provides customers with HRC wall panels that meet the criteria of green materials:

Green production: HRC wall panels are made from closed production technology from Japan, strictly controlling input materials. Non-fired, smokeless materials, waste treatment of materials, closed production waste and no impact on the surrounding environment. As a result, it helps to create products with the best quality.

HRC wall panels made from Japanese technology

Cost savings: The material can be recreated for use, thus helping the investor save more costs than traditional brick walls, causing waste. As a result, improving labor costs, reducing material costs ---> reducing maintenance costs.

>>Find more about green materials in construction

HRC wall panels can be reused for other industrial works

Fire protection, superior waterproofing: Wall panels used as partitions, walls factory cover with fire resistance up to 120-150 minutes. Moreover, the material does not penetrate and crack the surface during use.

Fast construction: Construction time is reduced by 1/4 compared to traditional brick building methods. Using 1 crane and 5 workers perform simple operation, neat construction surface is the outstanding advantages of HRC Vietnam prefabricated concrete products.

>>More information of precast concrete materials

HRC wall panels – precast concrete slabs used for industrial works

Environmentally friendly: No waste of materials, capable of conversion and reuse for other industrial buildings ---> environmentally friendly HRC materials.

Therefore, HRC materials are the optimal solution for investors.

Eco-friendly HRC wall panels

Hopefully, with the information provided about the materials used in construction, customers can choose the right material for their work. If you want to optimize the cost of raw materials for your work, ensure the building is durable, materials are used for a long time, please contact hotline 0981158591 for HRC Green Materials Vietnam for the most detailed advice

.jpg)