Industry news and documents

Top 8 factory building materials leading the trend in 2022

With the advanced technical level, the need for construction increasingly requires high technology, people gradually have an interest in green materials to protect the environment. Here are the top 8 factory building materials favored in Vietnam today, forecasted to lead the trend in 2022. Let's find out with HRC Vietnam what types of factory building materials are through this article!

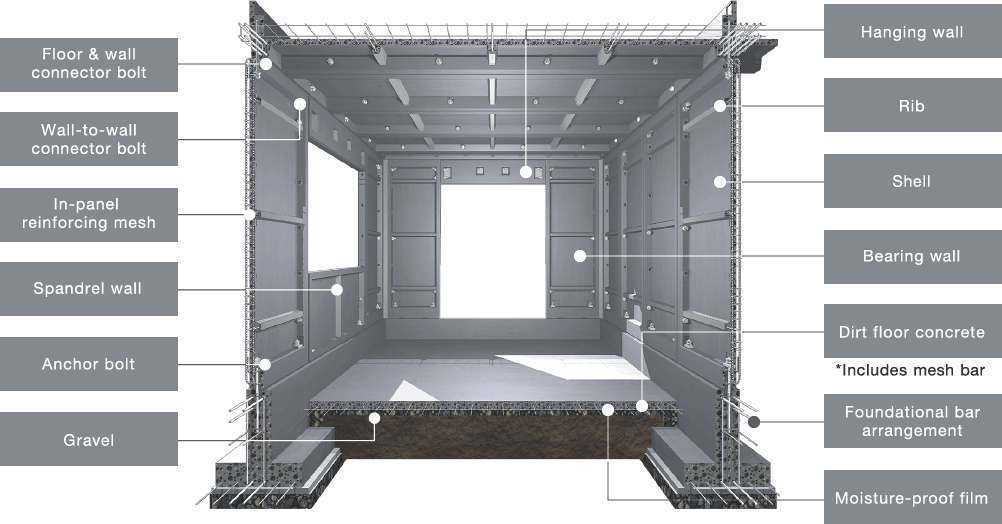

Factory Building Materials - Hrc Vietnam Prefabricated Reinforced Concrete Wall Panels

With many outstanding advantages such as bearing capacity, heat resistance, good moisture resistance, long life, saving costs and construction time, precast reinforced concrete wall panels are increasingly important in the construction industry, which can be considered as one of the best factory building materials available today. The product is made from cement, sand and additives, all of which are natural materials, safe for human health and environmentally friendly, making the product greener. In the coming time, prefabricated reinforced concrete wall panels are expected to completely replace traditional types of concrete and brick construction.

Precast reinforced concrete wall panels are widely used in factory construction works

HRC Vietnam is one of the pioneering construction companies in bringing precast technology from Japan to vietnam, helping to create precast reinforced concrete slabs with a variety of designs and outstanding quality. Before being brought to the construction works, all factory building materials will be thoroughly tested structurally and quality to ensure the product is always in the best condition.

HRC Vietnam specializes in manufacturing, constructing and installing prefabricated reinforced concrete wall panels for factory and warehouse works. Contact HRC Vietnam immediately if you want to find out more information about precast reinforced concrete slabs!

NanoTechnology Cement - SCG's proprietary building material

Nanotechnology cement is a new building material with exclusive technology of SCG Group, called SCG Super Cement. This is the only cement product produced according to Nanotechnology in Vietnam today. Nano cement has high hardness and durability because it is made from nano-sized cement molecules, so it binds very closely, limiting cracking and leaking.

Nanotechnology cement is a breakthrough innovation, helping to improve the quality of construction works

Nano cement can be used for brick lining, plastering, foundation concrete,... in the construction works of factories and factories with high certainty, sustainable over time.

Ceramic tiles, antibacterial porcelain - Factory building materials are safe for health

Ceramic tiles, antibacterial porcelain is a new product line in the technology of producing ceramic tiles, porcelain has the ability to protect human health and be environmentally friendly. The outstanding advantage of this material is the ability to self-destroy bacteria, mold and toxic substances that cling to the surface of the product, anti-adhesion, easy to clean.

Ceramic tiles, antibacterial porcelain have the ability to kill bacteria, smooth surface, easy to clean, bring safety to users

Energy-saving glass - Green factory building materials in Vietnam

Building materials have recently emerged in the Vietnamese market which is energy-saving glass. Energy-saving glass is a factory building material that has only appeared in Vietnam in the past few years, produced with extremely modern technology, meeting the necessary standards of green and environmentally friendly buildings, which is expected to become a trend in Vietnam in the next few years.

Energy-saving glass is a new green technology building material in Vietnam

Popular energy-saving construction glass in Vietnam include Low-E glass and Solar Control glass.

-

Low-E (Low Emissivity): The type of glass produced by covering the surface of the white glass workpiece a special compound, contributing to reduce the amount of ultraviolet and infrared rays transmitted through the glass but still ensuring the amount of light transmitted into the factory. In the summer, Low-E glass prevents heat from transmitting from the outside to the room, helping to keep the space inside the plant always cool, thereby saving electricity when using the cooling system. In winter, Low-E glass prevents heat release from inside the factory, helping the room to always warm, saving electricity when using the fireplace.

-

Solar Control Glass: Solar Control glass is produced by coating ultra-thin layers composed of metal or metal oxide on the surface of white glass workpieces. This is a glass that reflects up to 65% of the sun's energy, 99% of the UV rays transmitted into the inside of the plant. This helps keeping the factory space always cool, protects human health and saves the energy of the air conditioning system.

AAC Concrete Tiles - Green Building Materials

AAC concrete brick (short for Autoclaved Aerated Concrete or Autoclaved Cellular Concrete) is an ultra-light non-fired brick with a super-light mass, a texture of tiny air bubbles shaped like a hive. AAC concrete bricks are also known as angular concrete bricks. AAC concrete bricks are produced from materials that are safe for human health as well as environmental protection, including sand, lime, aluminum powder, gypsum, cement.

AAC concrete bricks are considered as one of the materials to build green factories for safety with human health, can be reused many times.

AAC concrete tiles have light weight, soundproofing, good insulation, high durability and environmental friendliness. Therefore, this type of brick is being gradually replaced for traditional bricks, helping to reduce the weight of the building, shortening the construction time, which is very suitable for making factory building materials.

ALC Panels - New Factory Building Materials

ALC panel (Autoclaved Lightweight Concrete) also known as pressurized air-conditioned reinforced concrete. The invention of the ALC panel is a remarkable step forward in the field of building materials. The material for producing ALC panels is similar to AAC concrete bricks.

ALC Panels - New Factory Building Materials

This type of material has the outstanding advantage that the light volume and ease of construction should be commonly applied in the construction of walls and partitions of the factory.

Light Concrete Wall Panels - New Materials in Factory Construction

Light concrete wall panels are increasingly applied in construction works, especially those that require fast construction time but still ensure quality. Materials for creating lightweight concrete wall panels usually have cement, fine sand, plaster, Polypropylene fiber, EPS foam beads, additives,... This type of building material is also recyclable, so it is considered very environmentally friendly, not toxic to human health.

Light concrete wall panels are factory building materials with high bearing capacity, insulation, noise resistance, material savings

Lightweight concrete wall panels have relatively good sound insulation, heat insulation and bearing capacity, excellent fire resistance, so they are used by contractors to make factory building materials.

Cemboard Precast Light Concrete Slab

Cemboard precast light concrete slabs are made from Portland cement, fine sand, cellulose fibers. This type of factory building material has many outstanding advantages such as low cost, construction time, quick installation and does not require highly qualified workers, thereby reducing construction costs should be widely used in Vietnam as well as many other countries.

Cemboard precast light concrete slabs are considered green factory building materials, which are very suitable for the tropical monsoon climate in Vietnam

Above is all the information about the top 8 factory building materials that are forecasted to lead the 2022 trend that HRC Vietnam wants to share with customers. If you need more advice, do not be afraid to contact HRC Vietnam's hotline number! We are always ready to serve you 24/7.

.jpg)